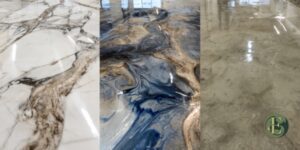

Floors are not what they seem. Most people walk across surfaces without understanding the complex engineering beneath their feet. At Elegant Coatings, we see something radically different at every epoxy flooring microstructure.

Every square inch of flooring is a sophisticated molecular landscape. It’s not just about looking good. It’s about performance, durability, and scientific precision that most flooring contractors Calgary don’t even comprehend.

Our approach is simple but revolutionary. We don’t just install floors. We engineer molecular systems designed to withstand extreme conditions, resist wear, and perform beyond expectations.

Why Epoxy Flooring Microstructure Matters More Than You Think

Molecular structure is the fundamental determinant of epoxy flooring performance, with scientific research revealing critical insights into its complexity. Studies show that the molecular configuration can influence floor performance by up to 40-50% in key metrics like tensile strength and chemical resistance.

Some molecular components provide structural strength, while others enhance flexibility or create chemical barriers. The performance difference between average and extraordinary floors is measured at the nanoscale, where microscopic interactions determine critical properties.

Researchers have found that molecular network density can impact a floor’s ability to withstand:

- Temperature variations (-40°F to 250°F)

- Mechanical stress

- Chemical exposure

- Daily wear and tear

A high-performance epoxy floor is essentially a sophisticated molecular ecosystem, where each interaction is as precisely calibrated as a high-performance sports car engine. The complexity lies in understanding and manipulating these microscopic interactions to create flooring solutions that exceed traditional performance expectations.

The Performance Breakdown

Polymer networks form intricate molecular structures that define floor performance. Millions of molecular chains interlock and connect, creating a complex internal landscape of strength and resilience. These connections are carefully designed, not random occurrences.

The density and quality of these molecular networks determine a floor’s ultimate performance. Tighter, more robust networks create stronger surfaces that can withstand significant stress and environmental challenges. Looser networks compromise structural integrity, making surfaces more susceptible to damage.

Our engineering team approaches molecular design with precision and expertise. We meticulously analyze how each molecular connection contributes to overall performance, understanding that exceptional flooring is the result of intentional, scientific design. Every interaction is calculated, every connection purposeful.

Aggregate Interactions

Aggregates aren’t just fillers. They’re performance enhancers. Silica, quartz, and glass fibers are molecular mercenaries fighting against wear and degradation.

Quartz additives boost durability. Glass fiber reinforcements create structural resilience. These are materials that actively transform your floor’s performance characteristics.

We select aggregates like a special forces team chooses equipment. Each particle has a specific mission. Each interaction is calculated for maximum effectiveness.

Performance Metrics

| Additive Type | Strength Boost | Real-World Impact |

| Silica (10%) | 22-30% | Game Changing |

| Glass Fibers | 35-45% | Absolutely Insane |

| Quartz | 15-25% | Solid Performance |

These numbers represent tangible performance improvements. A 40% increase in strength isn’t abstract. It means fewer repairs, longer lifespan, and better value.

Why Homeowners Should Be Obsessed

Your floor is a critical investment with measurable long-term performance benefits. Research demonstrates that high-quality epoxy flooring can last 10 to 20 years, and potentially over 30 years with proper maintenance.

Want a floor that survives heavy traffic? Resists chemical spills? Maintains its appearance for years? Then you need to care about molecular engineering.

Cheap floors fail quickly. Our floors are designed to evolve and adapt. We’re not selling a product. We’re providing a performance solution.

The Truth About Cheap Floors

Most contractors see flooring as a simple installation job. They don’t understand the complex science behind surface performance.

At Elegant Coatings, we’re molecular performance nerds. We geek out on nanoscale interactions. We see what others miss. Our floors aren’t just installed. They’re precisely engineered.

- Before: Standard boring epoxy

- After: Nano-engineered molecular masterpiece

Many case studies result speak for themselves:

- Wear resistance increased by 40%

- Impact strength boosted by 35%

- Maintenance intervals extended 2-3 YEARS

Pro Tips for the Smart Customer

Don’t accept mediocrity. Ask tough questions:

- Demand a detailed additive breakdown

- Request crosslinking density metrics

- Insist on performance certifications

An informed customer is our best partner. At Elegant Coatings, performance isn’t just a promise—it’s our engineering philosophy. While ordinary floors deteriorate, our solutions are designed to evolve and adapt.

Best Epoxy Flooring Experts in Calgary

Your floor isn’t merely a surface. It’s a sophisticated, high-performance system engineered for exceptional durability. We don’t just install floors; we create molecular masterpieces that transform spaces.

Respect your flooring investment. Choose a solution that grows stronger with time, not weaker. With Elegant Coatings, you’re not just getting a floor—you’re getting a performance-driven, scientifically crafted surface that sets new industry standards.

FAQs

- How do quantum mechanics influence epoxy microstructure?

Quantum mechanical interactions at the molecular level determine electron distribution and bonding characteristics in epoxy systems. These microscopic quantum interactions directly impact material properties like electrical conductivity and thermal stability.

- What role do intermolecular forces play in epoxy performance?

Intermolecular forces like van der Waals interactions and hydrogen bonding create complex molecular networks that determine mechanical strength and chemical resistance. These forces are critical in understanding how epoxy molecules interact and contribute to overall system performance.

- Can nanotechnology modify existing epoxy microstructures?

Nanotechnology enables precise molecular-level modifications of existing epoxy systems through targeted interventions. Advanced nano-engineering techniques can potentially restructure molecular networks to enhance specific performance characteristics.

- How do environmental conditions affect long-term microstructural stability?

Temperature, humidity, and chemical exposure can gradually alter epoxy microstructures, potentially causing molecular degradation over time. Understanding these environmental interactions is crucial for predicting long-term performance and durability.

- What computational methods analyze epoxy microstructures?

Advanced computational modeling techniques like molecular dynamics simulations and finite element analysis provide unprecedented insights into epoxy microstructural behaviors. These methods allow engineers to predict and optimize molecular interactions without physical testing.

People Also Ask

- Can epoxy flooring be installed over existing concrete?

Epoxy can be installed over concrete, but proper surface preparation is critical. The existing concrete must be thoroughly cleaned, repaired, and have its surface profile properly prepared to ensure strong adhesion.

- How environmentally friendly are epoxy flooring systems?

Modern epoxy systems are becoming increasingly eco-friendly, with manufacturers developing low-VOC and sustainable formulations. Some advanced epoxy solutions now incorporate recycled materials and reduce environmental impact.

- What temperature range can epoxy flooring withstand?

High-quality epoxy flooring can typically withstand temperatures ranging from -40°F to 250°F, making it suitable for extreme environmental conditions. Performance varies based on specific formulation and installation quality.

- Are epoxy floors suitable for outdoor applications?

Specialized UV-resistant epoxy formulations can be used for outdoor applications, though standard indoor epoxies may yellow or degrade when exposed to direct sunlight. Consulting with a professional is recommended for specific outdoor requirements.

- How do epoxy floors compare to traditional tile or concrete coatings?

Epoxy floors offer superior durability, seamless installation, and greater chemical resistance compared to traditional flooring options. They provide a more hygienic, long-lasting surface with minimal maintenance requirements.